Best electronic component adhesive glue manufacturers in china and areas of application

Best electronic component adhesive glue manufacturers in china and areas of application

The best electronic component adhesive manufacturer has entered the market to satisfy the rising demand for high-quality solutions. In the assembly and manufacture of electronics, adhesives have resoaked the traditional process like soldering. Adhesives are the best at providing the strongest bonds to hold different components in place. The best adhesives are also the best for protecting the different electronic components against corrosion, vibrations, and all sorts of environmental hazards.

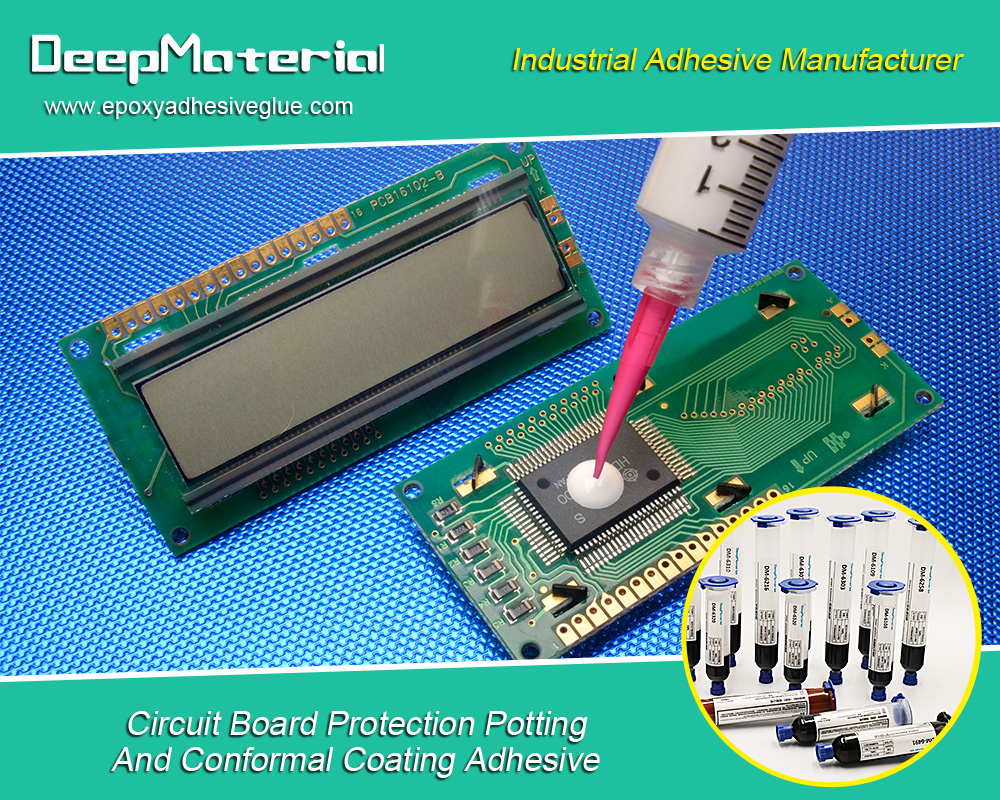

Adhesives can be used for different purposes like conformal curing and encapsulating PCBs. They are also good for potting, wire tacking, and surface mounting devices. A wide range of adhesive technologies available can meet different application needs.

Main applications

The best electronic component adhesive manufacturers create adhesives that can meet different market demands. At DeepMaterial, we understand that each application is unique; therefore, there is a no size fits all adhesive. In addition, different surfaces have different needs, so we have a line of products to satisfy everyone’s needs.

Some of the main applications include:

Bonding circuit boards with surface mount devices: SMDs or surface mount devices are usually placed by adhesive beads. The adhesive can then be cured by exposing it to UV radiation and heat. This process holds the SMDs in place until they are soldered. Urethane acrylates epoxies, and single-component acrylics can be used to serve this purpose.

Wire tacking: in this case, the best electronic component adhesive manufacturer also offers solutions for wire tacking. This kind of adhesive aims to reinforce your wired connections. Here, the adhesive gets bonded to the board, protecting it from vibrations. The adhesives used in wire tacking include light curable acrylics, epoxies, and cyanoacrylates.

Encapsulation and potting: this is the process where the entire assembly is immersed in an adhesive. By so doing, the components are kept safe from any physical damage. This also offers additional insulation. Typically, acrylics, silicones, polyurethanes, and epoxies are used for potting purposes.

Conformal coatings: the best electronic component adhesive manufacturers create the best options for conformal coatings. This is where a thin film of resin adheres to the board. To apply, spraying is the most commonly used method. These coatings offer protection to different components and allow them to remain isolated. The common choices include acrylics, silicones, polyurethanes, and epoxies.

Adhesive properties for electronics

DeepMaterial is the best electronic component adhesive manufacturer with a wide range of products to select from when you want a quality product for electronics. Different adhesives can be used on electronics. The different types come with their specific properties.

Most adhesives available in the market are not conducive as far as electricity is concerned. To achieve conductivity, you would need to add a filler. This filler is added to your base material. The most commonly used fillers include carbon, nickel, and silver. Epoxy resin is the most commonly used base material.

Other adhesives are thermally conductive. In such a case, the adhesive transfers heat from sensitive electronics. This heat is dissipated through different heat sinks. Such systems can be created using acrylics, silicone, and epoxies.

Finding the best electronic component adhesive manufacturer guarantees you the highest quality and the best outcome. In addition, electronics are sensitive, so DeepMaterial makes the most functional adhesives to meet the demand.

For more about best electronic component adhesive glue manufacturers in china and areas of application,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/electronic-adhesives-glue/ for more info.