The Future of optical bonding adhesive: Innovations and Advancements

The Future of optical bonding adhesive: Innovations and Advancements

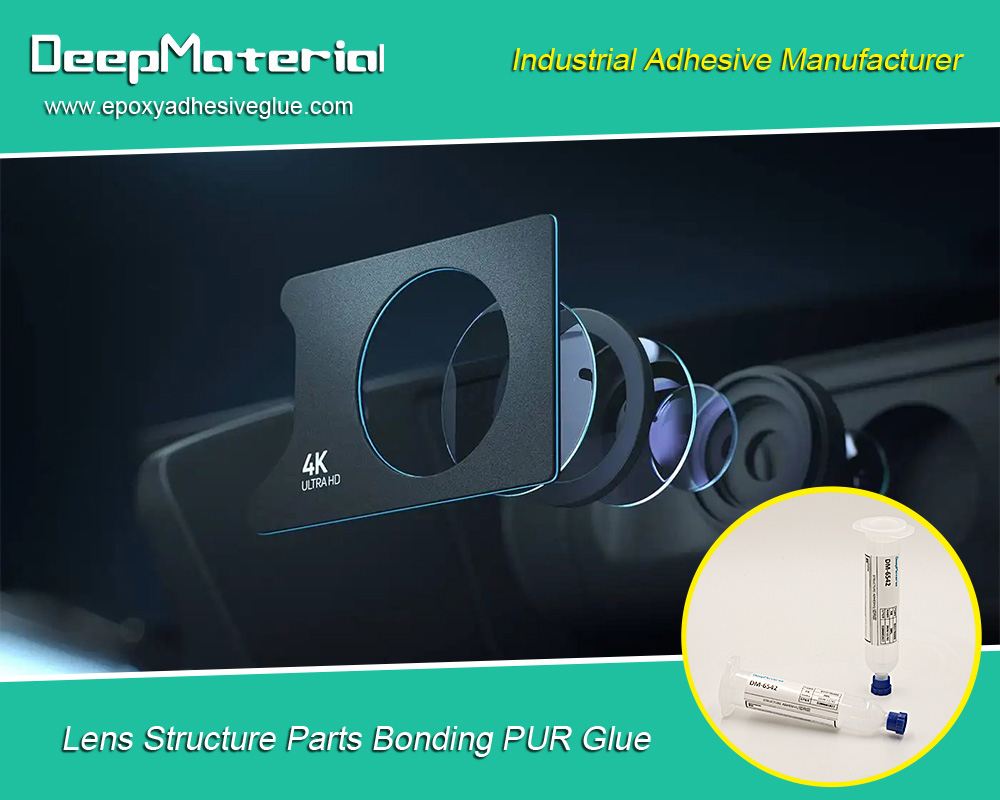

Optical bonding adhesive has been a game-changer in the display industry, providing a seamless and durable bonding solution for touchscreens, LCDs, and other electronic displays. As technology continues to evolve, so does the demand for more advanced and innovative bonding solutions.

We will explore the future of this adhesive and the latest advancements that are set to revolutionize the industry. From improved optical clarity to enhanced durability, we will delve into the exciting developments that are shaping the future of this critical technology.

Basics of Optical Bonding Adhesive

This is a type of adhesive that is used to bond two or more optical components together. It is typically made up of a polymer resin that is applied between the two surfaces to be bonded. The adhesive is then cured using heat or ultraviolet light to create a strong bond between the two surfaces.

There are several types of such adhesive available on the market today. Some of the most common types include acrylic, silicone, and epoxy adhesives. Acrylic adhesives are known for their high strength and durability, while silicone adhesives are known for their flexibility and resistance to high temperatures. Epoxy adhesives are often used in applications where high strength and chemical resistance are required.

Advancements in Optical Bonding Adhesive Technology

Advancements in Optical Bonding Adhesive Technology

In recent years, there have been significant advancements in optical bonding technology. These advancements have led to improved performance and increased demand for this type of adhesive.

One of the most significant advancements in optical bonding technology has been the development of new materials that offer improved performance characteristics. For example, some new materials offer improved adhesion strength, while others offer improved resistance to high temperatures or chemicals.

Another significant advancement has been the development of new curing methods that allow for faster curing times and improved bond strength. For example, some new curing methods use ultraviolet light instead of heat to cure the adhesive, which can significantly reduce curing times.

The Role of Optical Bonding Adhesive in Display Manufacturing

This adhesive plays a crucial role in display manufacturing. It is used to bond the various layers of a display together, including the cover glass, touch sensor, LCD panel, and backlight module.

One of the primary benefits of using this adhesive in display manufacturing is improved optical clarity. By bonding the various layers together with an adhesive, manufacturers can eliminate air gaps between the layers that can cause reflections and reduce image quality.

Another benefit of using such adhesive in display manufacturing is increased durability. By bonding the various layers together with an adhesive, manufacturers can create a more robust display that is less likely to crack or break.

Optical Bonding Adhesive in Automotive and Aerospace Industries

It also plays a crucial role in the automotive and aerospace industries. It is used to bond windshields and other windows together to improve optical clarity and durability.

One of the primary benefits of using such adhesive in these industries is improved safety. By bonding windshields together with an adhesive, manufacturers can create a more robust windshield that is less likely to shatter during an accident.

Another benefit of optical bonding adhesive in these industries is improved aerodynamics. By eliminating air gaps between windows with an adhesive, manufacturers can reduce drag on vehicles and aircraft, which can improve fuel efficiency.

Optical Bonding Adhesive in Medical and Scientific Applications

It is used to bond various components together to improve optical clarity and durability. One of the primary benefits of using optical bonding adhesive in these applications is improved image quality. By eliminating air gaps between components with an adhesive, manufacturers can create clearer images that are easier to analyze.

Another benefit of using optical bonding adhesive in these applications is increased durability. By bonding components together with an adhesive, manufacturers can create more robust equipment that can withstand harsh environments.

The Benefits of Optical Bonding Adhesive for Outdoor Displays

Optical bonding adhesive also offers several benefits for outdoor displays. Outdoor displays are exposed to harsh environments such as extreme temperatures, moisture, dust, and sunlight.

One of the primary benefits of using optical bonding adhesive for outdoor displays is increased durability. By bonding the various layers together with an adhesive, manufacturers can create a more robust display that can withstand harsh outdoor environments.

Another benefit of using optical bonding adhesive for outdoor displays is improved readability. By eliminating air gaps between layers with an adhesive, manufacturers can reduce reflections on the display surface that can make it difficult to read in bright sunlight.

The Future of Optical Bonding Adhesive: Predictions and Trends

The future looks promising for optical bonding adhesive technology. There are several predicted trends that could shape the future of this technology.

One trend is increased demand for thinner displays with higher resolution. This trend will require new materials with improved performance characteristics such as higher adhesion strength and increased resistance to high temperatures.

Another trend is increased demand for displays with curved surfaces. This trend will require new materials with improved flexibility characteristics such as increased elongation at break.

Challenges and Limitations of Optical Bonding Adhesive

Despite its many benefits, there are also challenges and limitations associated with optical bonding adhesive technology.

One challenge is achieving consistent bond strength across large surface areas. This challenge requires careful control over factors such as temperature, pressure, and curing time during the manufacturing process.

Another challenge is achieving consistent optical clarity across large surface areas. This challenge requires careful control over factors such as surface preparation and application technique during the manufacturing process.

Final Verdict

Final Verdict

In conclusion, optical bonding adhesive technology plays a crucial role in modern technology across various industries such as display manufacturing, automotive and aerospace industries, medical and scientific applications, and outdoor displays. Recent advancements have led to improved performance characteristics such as higher adhesion strength and increased resistance to high temperatures or chemicals.

The future looks promising for this technology with predicted trends such as increased demand for thinner displays with higher resolution or displays with curved surfaces requiring new materials with improved flexibility characteristics such as increased elongation at break.

For more about choosing the optical bonding adhesive, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/solutions/ for more info.