Enhancing Efficiency and Durability: The Role of Epoxy Resin for Electric Motors

Enhancing Efficiency and Durability: The Role of Epoxy Resin for Electric Motors

Electric motors are the backbone of modern industries, powering everything from household appliances to massive machinery. Efficiency and durability are paramount in their design and operation. One critical component that significantly contributes to these factors is epoxy resin. Epoxy resin is versatile and reliable for insulating and protecting electric motors against environmental and operational challenges. In this article, we delve into the significance of epoxy resin for electric motors, exploring its benefits, applications, and advancements in the field.

Benefits of Epoxy Resin for Electric Motors

Electric motors are the beating heart of countless industries, driving everything from manufacturing processes to transportation systems. Ensuring the reliability and longevity of these motors is paramount, and one crucial factor in achieving this is the choice of insulation materials. Among these, epoxy resin stands out as a top contender, offering many benefits that contribute to electric motors’ optimal performance and durability.

Let’s delve into the critical advantages of epoxy resin for electric motors:

- Superior Insulation Properties: Electric motors operate in varied conditions, often exposed to high voltages. Epoxy resin is a robust insulating material, effectively preventing electrical breakdowns by isolating conductive components from each other. This insulation capability is essential for maintaining motor efficiency and preventing potentially catastrophic failures due to electrical faults.

- Thermal Stability: Electric motors risk thermal degradation in environments with high temperatures. Epoxy resin comes to the rescue with its exceptional heat resistance, shielding against temperature-induced damage. Withstanding high temperatures, epoxy resin extends the lifespan of motor components, ensuring reliable operation even in the harshest thermal conditions.

- Chemical Resistance: Industrial settings often expose electric motors to corrosive chemicals and contaminants. Epoxy resin acts as a protective barrier, shielding motor components from chemical attacks and corrosion. This resistance to chemical degradation ensures the integrity of the motor over time, reducing maintenance needs and enhancing operational reliability in challenging environments.

- Mechanical Strength: Beyond insulation and thermal protection, electric motors require robust structural support to withstand mechanical stresses. Epoxy resin offers impressive mechanical strength, reinforcing motor components and reducing the risk of mechanical failures. With enhanced durability, motors encapsulated in epoxy resin can endure demanding operating conditions without compromising performance.

- Customizable Formulations: One size does not fit all regarding electric motors and their operational requirements. Epoxy resin allows manufacturers to tailor formulations to specific performance needs. Whether it’s improving thermal conductivity, enhancing flame retardancy, or achieving other desired characteristics, epoxy resin can be customized to meet the unique demands of various applications. This versatility empowers engineers to optimize motor designs for maximum efficiency and reliability.

Applications of Epoxy Resin in Electric Motors

In the realm of electric motors, where efficiency and durability are paramount, incorporating epoxy resin is a crucial innovation. This versatile material finds myriad applications within electric motors, from insulation to encapsulation, ensuring optimal performance and longevity. Let’s delve into the various ways epoxy resin elevates the functionality of electric motors:

- Stator and Rotor Insulation: Epoxy resin plays a pivotal role in safeguarding the heart of electric motors—the stator and rotor windings. By encapsulating these essential components, epoxy resin forms a protective barrier that mitigates the risk of electrical short circuits. Furthermore, it shields the windings from environmental elements such as moisture, dust, and contaminants, enhancing the motor’s reliability and longevity.

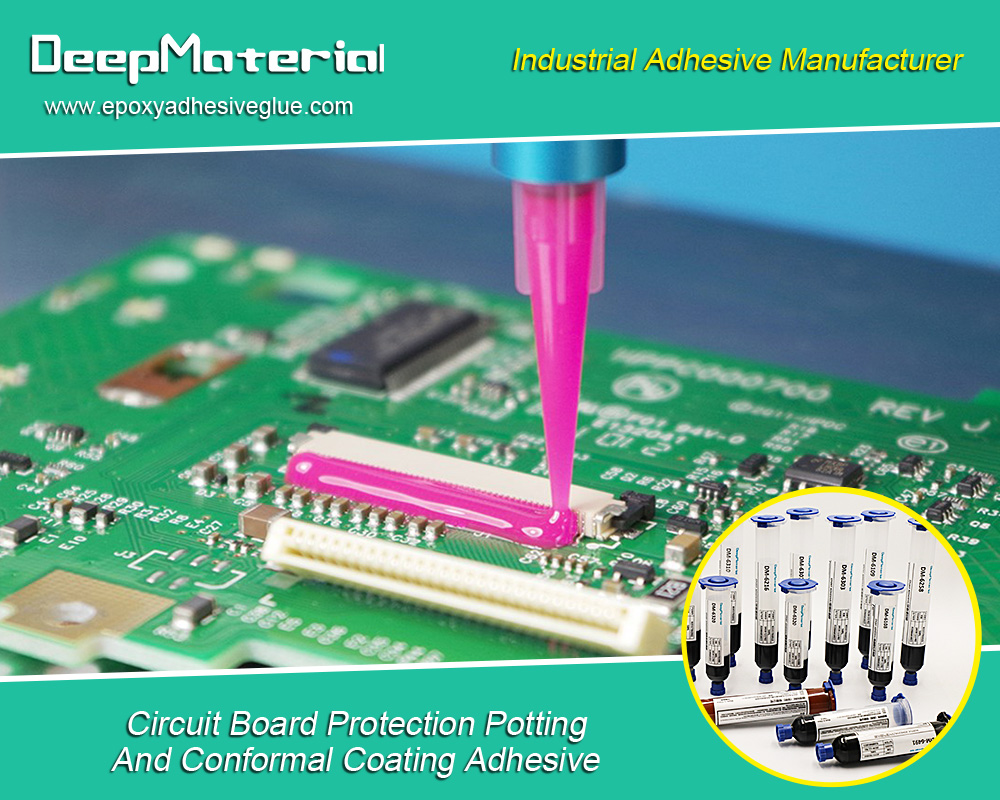

- Potting and Encapsulation: Potting and encapsulation techniques involve filling motor enclosures or encapsulating specific components with epoxy resin. This process offers an additional layer of defense against external threats like moisture ingress, dust particles, vibrations, and mechanical shocks. By sealing sensitive components within a durable epoxy matrix, manufacturers ensure that electric motors remain resilient in diverse operating conditions, from industrial to outdoor environments.

- Magnet Bonding: In electric motors utilizing permanent magnets, the secure attachment of magnets to rotor assemblies is paramount for optimal performance. Epoxy resin is an ideal adhesive for bonding magnets, facilitating robust adhesion and precise alignment. This ensures that the motor’s magnetic field remains stable, enhancing efficiency and minimizing energy losses.

- Coating and Sealing: Epoxy resin coatings are applied to motor surfaces to fortify them against many challenges. These coatings act as a protective shield, guarding against moisture infiltration, chemical exposure, and abrasion. By sealing surface irregularities and micro-fissures, epoxy resin coatings enhance electric motors’ insulation properties, extending their service life and reducing the risk of premature failure.

The widespread adoption of epoxy resin within electric motors underscores its unparalleled versatility and efficacy in enhancing performance and durability. Whether insulating critical components, encapsulating sensitive parts, bonding magnets, or sealing surfaces, epoxy resin is a cornerstone of modern motor design.

As the demand for energy-efficient and reliable electric motors continues to soar across various sectors, the importance of epoxy resin as a critical enabler cannot be overstated. Its ability to fortify motor components against harsh operating conditions while optimizing performance underscores its indispensable role in shaping the future of electromechanical systems.

Advancements in Epoxy Resin Technology

Nanocomposite Formulations: Researchers are exploring nanocomposite epoxy resin formulations infused with nanoparticles to enhance mechanical, thermal, and electrical properties. These advancements promise even more excellent performance and reliability for electric motors.

- Low-Volatile Organic Compound (VOC) Formulations: Environmentally friendly epoxy resin formulations with reduced VOC emissions are gaining traction. These formulations comply with stringent environmental regulations while maintaining high-performance standards.

- High-Temperature Resistance: With the increasing demand for electric motors in high-temperature applications, there’s a growing focus on developing epoxy resin formulations with exceptional heat resistance. Advanced materials capable of withstanding extreme temperatures expand the range of applications for electric motors.

Moreover, using epoxy resin aligns with the industry’s pursuit of eco-friendly solutions. Many epoxy formulations boast low volatile organic compound (VOC) emissions and comply with stringent environmental regulations, thereby minimizing the ecological footprint of electric motor production and operation.

Conclusion

Epoxy resin plays a vital role in enhancing electric motors’ efficiency, durability, and reliability across various industries. Its superior insulation properties, thermal stability, chemical resistance, and mechanical strength make it indispensable for motor insulation, encapsulation, bonding, and coating. As technology advances, ongoing research and development efforts continue to improve epoxy resin formulations, pushing the boundaries of performance and opening new possibilities for electric motor applications. In pursuing sustainable and high-performance solutions, epoxy resin remains a cornerstone in the evolution of electric motor technology.

For more about enhancing efficiency and durability: the role of epoxy resin for electric motors, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.