Case In Germany: DeepMaterial Adhesive For Electric Motor Magnetic Bonding

In Germany, electro-motor is a mature industry. So magnets are everywhere and so is magnet bonding. It is an application used in a wide range of industries, including electrical machinery, power tools, the automotive industry, audio and video equipment, household appliances an other fields. The production of e-motors, in particular, is a booming industry in which magnet bonding plays a vital roles – especially when it comes to driving efficiency.

To meet the German customers’ manufacturing needs, DeepMaterial offer a comprehensive line of magnet bonding adhesives. Paired with technical expertise and high-quality equipment system solutions we support engineers within their design and production process.

How do magnet adhesives work?

Magnet bonding adhesives work by filling even the tiniest gaps in order to fix the magnet securely in position through a durable, high strength bond.

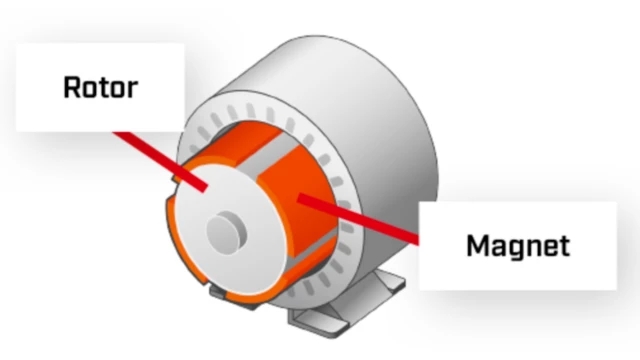

Surface Permanent Magnets (SPM)

Magnets are bonded to the outside surface of a laminated steel rotor that rotates. Therefore, adhesive should be strong enough to resist the centrifugal force.

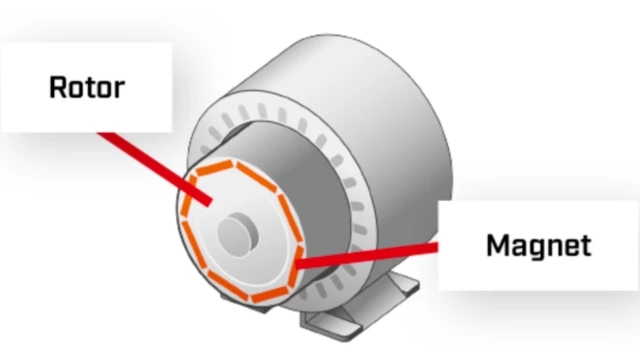

Internal Permanent Magnets (IPM)

Magnets are bonded inside the rotor or stator. This is usually done by dropping the magnets into existing slots and bonding them.

Industrial Adhesives for Bonding Metal, Glass, Magnet, and Motor Assembly

Activator-curing metal or structural adhesives brought about the technology revolution known as “cold bonding”. This type of technology shortens the assembly times associated with industrial metal and glass bonding and motor and magnet assembly. The materials cure upon exposure to UV/Visible light, heat (for shadow areas), or activator (for opaque surfaces). The adhesives bond glass, metal, plastic, ceramic, magnets, filled nylon, phenolic plastics, and polyamide, as well as dissimilar substrates. Fast cure time saves space, labor, and regulatory compliance costs making product assembly easier and more efficient for manufacturers.

Material Bonding Solutions are superior vs. Traditional Methods (clips or springs)

Due to uniform stress load and airtight gap closing, they avoid vibration and corrosion – thus extending the long lifetime of the device. Automation friendliness allows for cost reduction and simplified operation running.

Benefits of DeepMaterial Magnet Bonding Adhesives:

· Prevents air gaps

· Avoids vibrations

· Makes them impact resistant

· In comparison: Mechanical methods interfere with the magnetic field and will also put local stress on the magnet (prone to wear and tear). Also, air gaps will lead to vibration and can cause heat pockets to form (efficiency loss).

Dispensing is key to the DeepMaterial solution

Over the past years, we have designed, built and integrated advanced equipment solutions for our customers. From water-thin liquids to high-viscosity pastes, curing a wide variety of adhesives, sealants and other industrial fluids like acrylics, anaerobics, cyanoacrylates and epoxies.

With DeepMaterial high-quality equipment system solutions, we offer a complete line, comprehensive testing and global on-site engineering support to assist with consultation, repairs, joint product development, custom designs and more to fit our customers’ magnet bonding needs.

We’sre also looking for DeepMaterial industrial adhesive products cooperation global partners, if you want to be an agent of DeepMaterial’s:

Industrial adhesive glue supplier in America,

Industrial adhesive glue supplier in Europe,

Industrial adhesive glue supplier in UK,

Industrial adhesive glue supplier in India,

Industrial adhesive glue supplier in Australia,

Industrial adhesive glue supplier in Canada,

Industrial adhesive glue supplier in South Africa,

Industrial adhesive glue supplier in Japan,

Industrial adhesive glue supplier in Europe,

Industrial adhesive glue supplier in Korea,

Industrial adhesive glue supplier in Malaysia,

Industrial adhesive glue supplier in Philippines,

Industrial adhesive glue supplier in Vietnam,

Industrial adhesive glue supplier in Indonesia,

Industrial adhesive glue supplier in Russia,

Industrial adhesive glue supplier in Turkey,

……

Contact us now!