All you need to know about bonding commercial-grade lenses using Lens Bonding Adhesives

All you need to know about bonding commercial-grade lenses using Lens Bonding Adhesives

Commercial-grade lenses are used in the production of various optical equipment. These special instruments feature special components like lenses, prisms, microscopes, and cameras. They feature various commercial-grade lenses that are usually bonded to their housing and each other using special adhesives. These adhesives are specially-engineered cement that comes with various technical specifications. They are optically-clear glues that offer low shrinkage while also preventing the stresses on each glass lens.

What is lens bonding?

What is lens bonding?

Lens bonding involves the joining of two or more lenses to improve their optical performance to the desired level. This process involves the combination of several optical elements into a superior product component. The combination of various lenses with the use of adhesives is called adhesive optical bonding. It involves the application of adhesives to hold the lenses in position. Lens bonding is preferred over traditional mechanical joining processes because they make the final products less complex and more lighter. Bonding never adds any weight or size to the products. This is what makes adhesives the most preferred solution for product joining in industrial applications.

Optical bonding in lenses

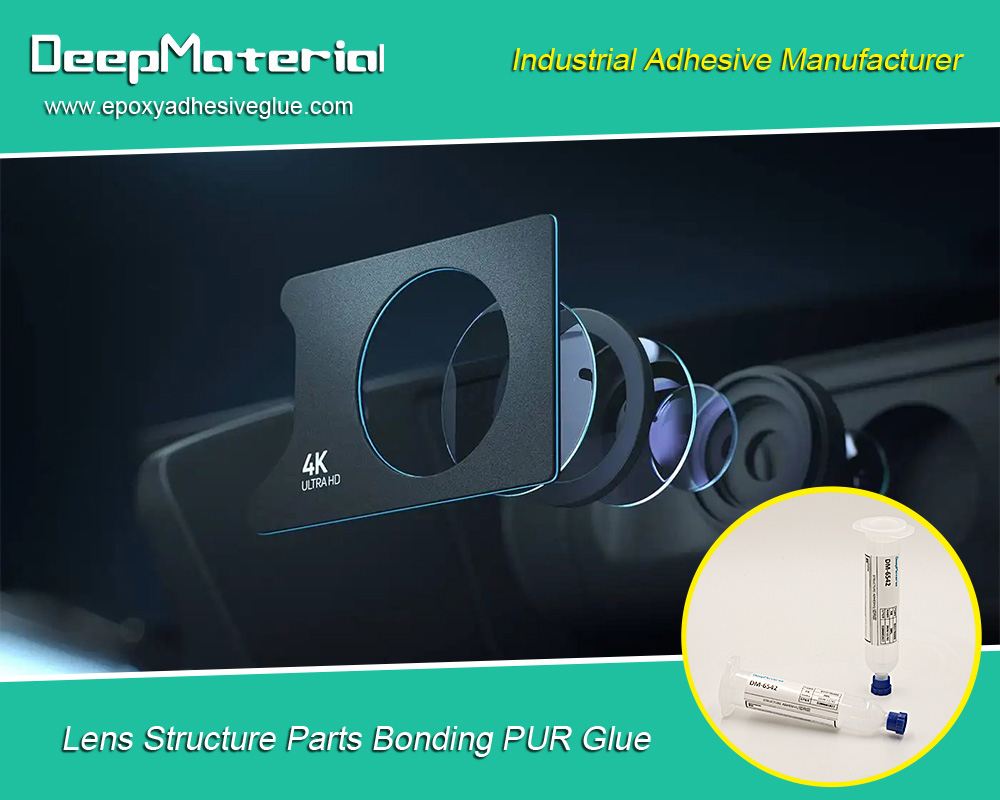

Lens bonding adhesives are used extensively in industrial lens bonding systems. Many manufacturers of photography optics, smartphones, cameras, and microscopes depend on these binders. This is because most lenses are made up of two or more lenses to produce a superior lens. Many lenses used to produce products in the optics industry feature instruments that consist of between 3 and 10 lenses. These lenses are necessary to produce high-quality images.

Lens bonding adhesives need to provide an optically-clear result. In addition, the final product should produce minimal out-gassing – a feature that is critical throughout the lens’ working life. These are important industrial adhesives that are known for remarkable UV stability and high thermal resistance. They are also known for their minimum shrinkage, which is a useful function for optimal lens operation.

Lens bonding adhesives are used to bond the cap of the lens in place – this is possible because of their excellent adhesive property to aluminum, ceramic, and glass.

Adhesives are known for their remarkable performances on the various materials that are used to produce optical components such as plastics, ceramics, metal, and glass. Due to their chemical components, lens-bonding adhesives are engineered to make optical devices more cost-effective, faster, and stronger. These are basic features that are in high demand in the marketplace.

Benefits of adhesives in lens bonding processes

Adhesive can be used to speed up the manufacturing process of lenses. It also helps to enhance and improve performance and reliability, while reducing costs. They are applied systematically in the production of camera lenses to evenly distribute stress loads over a wide large space. This way, the stress on that joint is reduced significantly. Because these adhesives are applied in the internal area of the joint, this makes it invisible in the final product assembly. Adhesives work to resist vibration and flex stresses while creating bonds and seals to help protect the internal parts of the cameras from extreme environments. Adhesives for lens bonding provide various benefits for camera production. These are some of the engineering benefits of the glue:

- They can be used to join various surfaces that come with irregular shapes.

- They help to add negligible weight to the general product assembly.

- When used, they do not alter the dimensions of the components.

- They can be automated easily.

Lens bonding adhesives: The various available adhesives

Lens bonding is an essential product-joining process that is used commonly in the assembly of optical instruments. There is a wide range of lens-bonding adhesives that product manufacturers use for the production of goods. Each one of these adhesives offers amazing benefits such as:

- Epoxies:Epoxies are commonly used by the optics industry for the production of compact and superior equipment. These special adhesives are generally one- or two-part structural glue that is known for their superior bonding properties. Epoxies can be used on various substrates while beneficial because of their low outgassing behaviour. Epoxies are used widely in the bonding of various camera components like lenses

- Acrylics:These are another set of adhesives that makes lens bonding very reliable. They produce similar performances to acrylics. When cured adequately, acrylic adhesives provide superior environmental, chemical, and thermal resistance. Since curing can be delayed, acrylic adhesives allow optimal product positioning to be achieved before setting. They are known for their high-strength bonds.

- Elastomers:Elastomers helps in the optics industry to ensure that the product assembly is fully robust. This is especially useful in the bonding of dissimilar materials such as metal to glass. Elastomers are rubber-like binders that produce sufficient flexibility for the glue to be worked into both substrates. They can cure easily in ordinary environmental conditions while also being highly resistant to moisture and heat. Elastomers are very versatile in industrial applications because they can be used on various substrates.

- Cyanoacrylates:Cyanoacrylates are also commonly used binders for the optical industry. They work to provide adequate structural bonding for a majority of optical assemblies. With Cyanoacrylates, the fixture strength of the product is achieved in about 24 hours. There have been recent advances in this type of industrial adhesive to enhance its benefits.

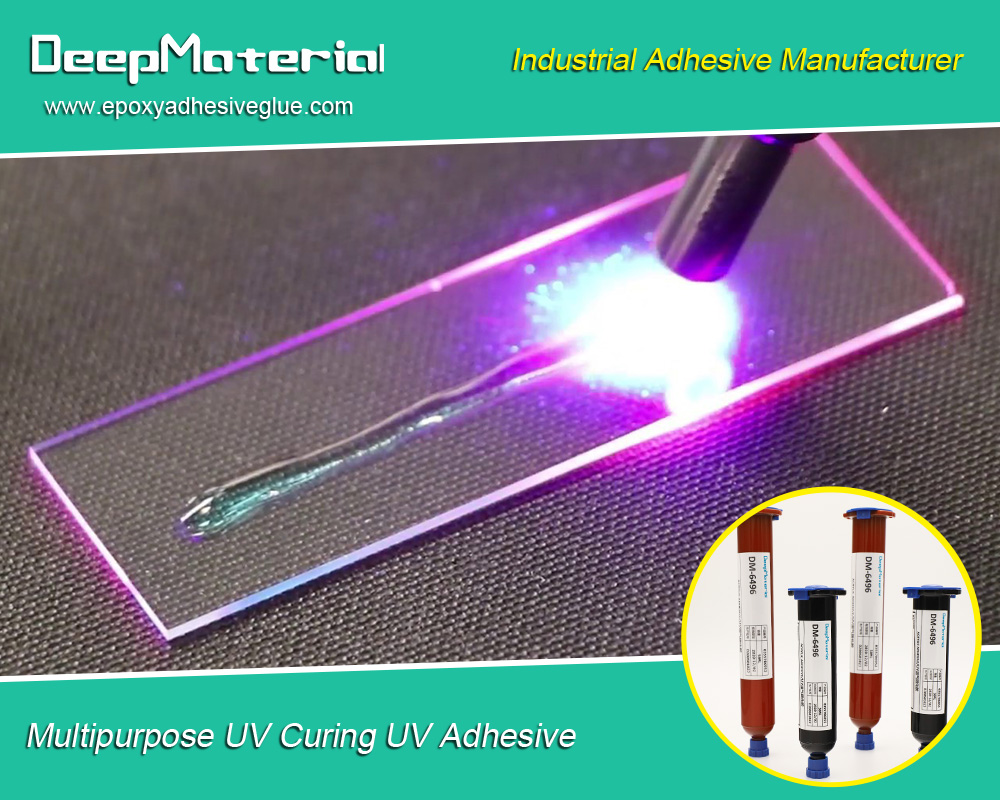

- Ultra-violet adhesives:UV adhesives are essential binders that are used in the optics industry. One primary benefit of these types of adhesives is the fact that they cure very rapidly.

Benefits of lens bonding adhesives

Lens bonding is a special type of joining process that is used by the optics industry. It involves the application of special adhesives to achieve optimal performance. Some of the benefits of adhesive optical bonding include:

- It offers remarkable adhesion to metallic substrates that are difficult to bond.

- It offers flexible curing times which permits proper material positioning.

- The final bond is resistant to extreme environmental conditions.

- The bonding glue does not affect the final sizes of the product.

- The adhesive bonds the optical substrates together to increase their compactness and weight.

Getting a special lens bonding glue for your production facility

For lens bonding adhesives to work as they should, they should be able to produce optically clear results. These are special binders that are used to glue all types of synthetic lenses and glasses. Many manufacturers of lens-bonding superglue usually obtain their products by using epoxies and acrylates as bases.

For more about all you need to know about bonding commercial-grade lenses using Lens Bonding Adhesives,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/lens-bonding-adhesive-solutions-from-deepmaterial-optical-bonding-adhesive-manufacturers/ for more info.