BGA Package Underfill Epoxy

High Fluidity

High Purity

Challenges

Electronic products of aerospace and navigation, motor vehicles, automobiles, outdoor LED lighting, solar energy and military enterprises with high reliability requirements, solder ball array devices (BGA/CSP/WLP/POP) and special devices on circuit boards are all facing microelectronics. The trend of miniaturization, and thin PCBs with a thickness of less than 1.0mm or flexible high-density assembly substrates, solder joints between devices and substrates become fragile under mechanical and thermal stress.

Solutions

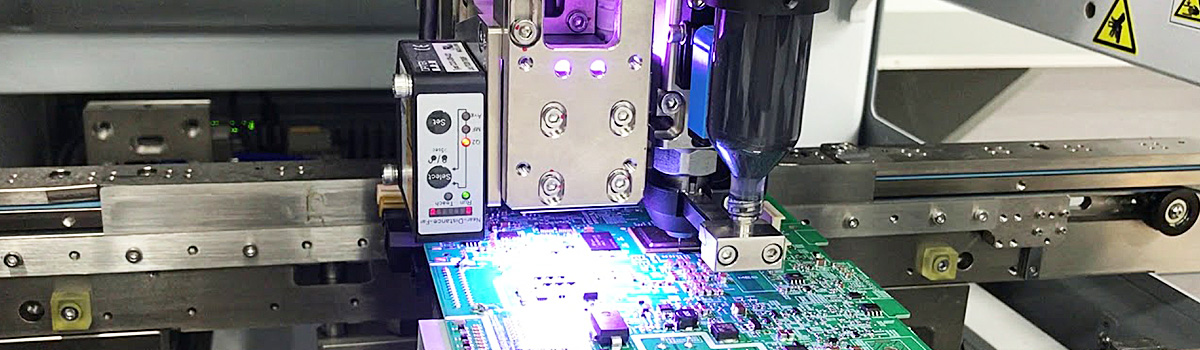

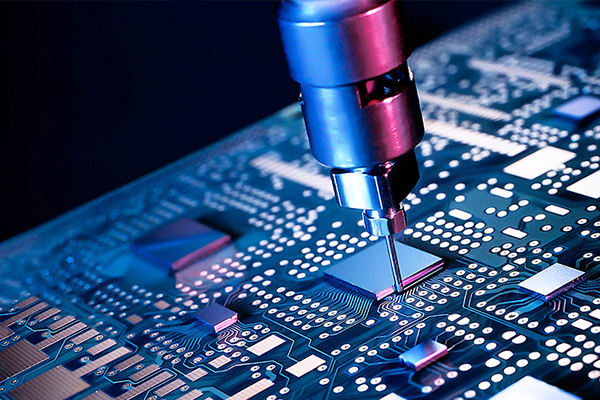

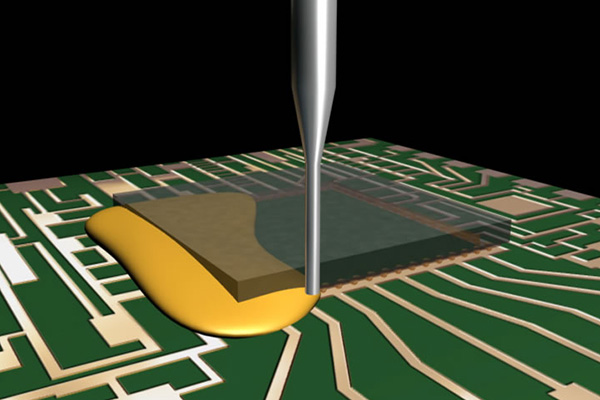

For BGA packaging, DeepMaterial provides an underfill process solution – innovative capillary flow underfill. The filler is distributed and applied to the edge of the assembled device, and the “capillary effect” of the liquid is used to make the glue penetrate and fill the bottom of the chip, and then heated to integrate the filler with the chip substrate, solder joints and PCB substrate.

DeepMaterial underfill process advantages

1. High fluidity, high purity, one-component, fast filling and fast curing ability of extremely fine-pitch components;

2. It can form a uniform and void-free bottom filling layer, which can eliminate the stress caused by the welding material, improve the reliability and mechanical properties of the components, and provide good protection for products from falling, twisting, vibration, moisture, etc.

3. The system can be repaired, and the circuit board can be reused, which greatly saves costs.

Deepmaterial is low temperature cure bga flip chip underfill pcb epoxy process adhesive glue material manufacturer and temperature-resistant underfill coating material supppliers,supply one component epoxy underfill compounds,epoxy underfill encapsulant,underfill encapsulation materials for flip chip in pcb electronic circuit board,epoxy-based chip underfill and cob encapsulation materials and so on.