Electronics Encapsulation Epoxy: Protecting and Enhancing Electronic Devices

Electronics Encapsulation Epoxy: Protecting and Enhancing Electronic Devices

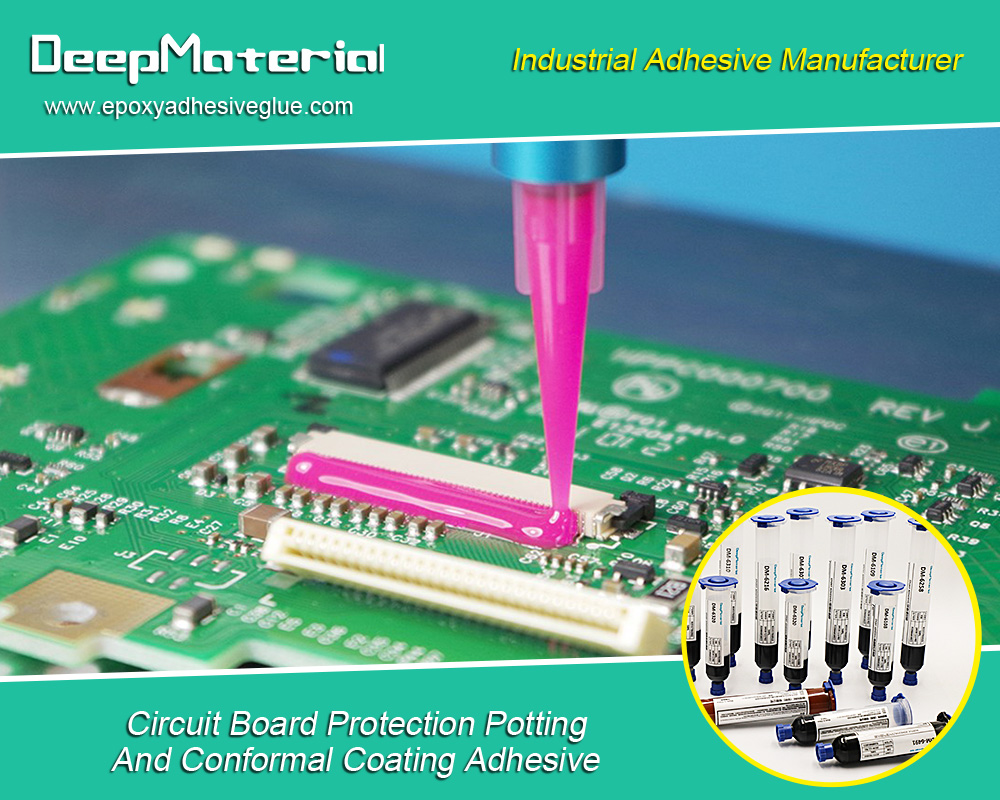

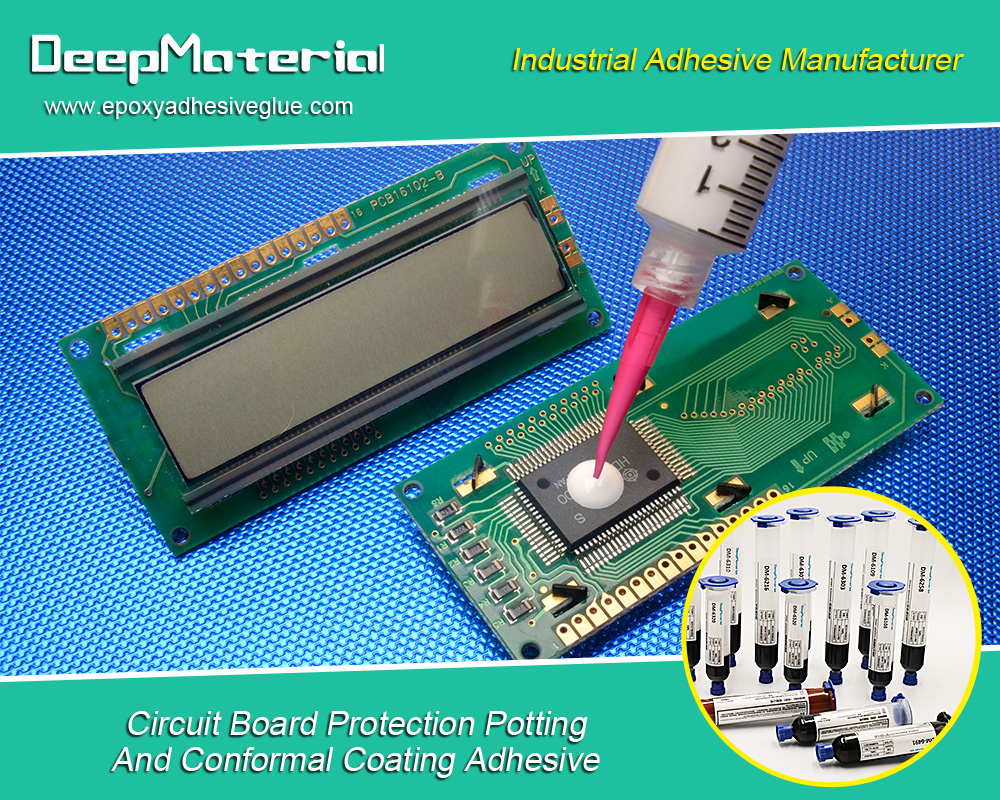

The demand for durability and reliability in modern electronics has skyrocketed. Encapsulation is one pivotal technique employed to ensure the longevity and efficiency of electronic components. Encapsulation involves enclosing electronic components in a protective layer of epoxy. This method, known as electronics encapsulation epoxy, serves multiple purposes, including protection against environmental factors, mechanical stability, and improved performance. This article delves into the intricacies of electronics encapsulation epoxy, exploring its significance, types, applications, and advantages.

Importance of Electronics Encapsulation Epoxy

Protection Against Environmental Factors

Electronic devices are often exposed to harsh environments that can compromise their functionality. Factors such as moisture, dust, and chemicals can lead to corrosion, short circuits, and overall degradation of electronic components. Encapsulation with epoxy provides a robust barrier, shielding the components from these harmful elements. The epoxy forms an airtight seal around the components, ensuring that external contaminants do not infiltrate and cause damage.

Mechanical Stability and Shock Absorption

Electronic devices are susceptible to mechanical stress and shocks from handling transportation or operational vibrations. Encapsulation epoxy offers significant mechanical stability by securing the components and absorbing any shocks or vibrations. This reduces the risk of mechanical failure, ensuring that the devices function optimally even in rugged conditions.

Thermal Management

Heat dissipation is a critical aspect of electronic device performance. Excessive heat can lead to overheating and eventual component failure. Epoxy encapsulation aids in thermal management by providing a medium for heat transfer. Specialized thermally conductive epoxies are designed to efficiently dissipate heat, maintaining the temperature within safe operating limits and enhancing the lifespan of the components.

Types of Encapsulation Epoxy

One-Component Epoxy Systems

One-component epoxy systems are pre-mixed and require no additional mixing before application. They are typically heat-cured, meaning they require elevated temperatures to initiate the curing process. Their simplicity of application makes them ideal for automated processes in large-scale manufacturing. However, the need for heat curing can be a limitation for temperature-sensitive components.

Two-Component Epoxy Systems

Two-component epoxy systems contain a resin and a hardener that must be mixed before application. The curing process begins once the two components are combined, and it can occur at room temperature or be accelerated with heat. This type of epoxy offers greater flexibility in terms of pot life and curing time, making it suitable for a wide range of applications. The ability to control the mixing ratio allows for customization of the final properties of the cured epoxy.

UV-Curable Epoxy Systems

UV-curable epoxy systems are designed to cure rapidly upon exposure to ultraviolet (UV) light. This type of epoxy is ideal for applications requiring fast curing times and minimal heat exposure. UV-curable systems are often used in precision applications where exact positioning and alignment are crucial. However, their effectiveness is limited to areas directly exposed to UV light.

Applications of Encapsulation Epoxy

Consumer Electronics

In consumer electronics, encapsulation epoxy is widely used to protect components in devices such as smartphones, tablets, and laptops. These devices are often exposed to daily wear and tear, and the epoxy helps maintain their functionality and extend their lifespan. Additionally, encapsulation enhances the water resistance of these devices, providing an added layer of security against accidental spills and splashes.

Automotive Electronics

The automotive industry relies heavily on electronic components for various functions, including engine control units (ECUs), sensors, and infotainment systems. These components are subjected to extreme conditions, including temperature fluctuations, vibrations, and exposure to automotive fluids. Encapsulation epoxy ensures these components remain operational by providing thermal stability, mechanical protection, and chemical resistance.

Industrial Electronics

Industrial environments can be particularly harsh, with dust, chemicals, and mechanical stress exposure. Electronic components used in industrial machinery, control systems, and robotics benefit from encapsulation epoxy. The epoxy safeguards the components from environmental damage, ensuring consistent performance and reducing downtime due to failures.

Medical Devices

Electronic devices such as diagnostic equipment, implants, and monitoring systems require high reliability and protection against biological contaminants in the medical field. Encapsulation epoxy is used to encapsulate sensitive electronics, ensuring their sterility and functionality. Certain epoxy formulations are biocompatible, making them suitable for use in medical applications.

Advantages of Electronics Encapsulation Epoxy

Enhanced Durability and Reliability

The primary advantage of encapsulation epoxy is the significant enhancement in the durability and reliability of electronic components. By providing a protective barrier, the epoxy ensures that the components can withstand harsh conditions and operate efficiently over an extended period. This reliability is crucial in applications where failure is not an option, such as in the aerospace, medical, and automotive industries.

Improved Electrical Insulation

Epoxy encapsulation offers excellent electrical insulation properties, preventing short circuits and electrical failures. This is particularly important in densely packed electronic assemblies, where the risk of electrical interference is high. The epoxy’s insulating properties ensure that the components function without interruption, even in close proximity to one another.

Customizable Properties

Epoxy systems can be formulated to meet specific requirements, such as varying degrees of hardness, flexibility, thermal conductivity, and curing time. This customization allows manufacturers to select the most suitable epoxy for their application, ensuring optimal performance. For example, a flexible epoxy might be chosen for applications requiring resistance to mechanical stress, while a thermally conductive epoxy would be ideal for heat management.

Cost-Effective Solution

Despite the advanced protection and performance benefits, epoxy encapsulation is cost-effective. Epoxy materials’ relatively low cost, combined with their ease of application, makes them an economical choice for protecting electronic components. Reducing failure rates and maintenance costs further contributes to overall cost savings.

Challenges and Considerations in Using Encapsulation Epoxy

Proper Mixing and Application

For two-component epoxy systems, precise mixing is critical to achieve the desired properties of the cured epoxy. Inaccurate mixing ratios can lead to incomplete curing or suboptimal performance. Additionally, the application process must ensure that the epoxy completely covers and adheres to the components without creating air bubbles or voids, which can compromise protection.

Thermal Expansion and Compatibility

The thermal expansion of the encapsulating epoxy must be compatible with the encapsulated components to prevent stress and potential damage during temperature fluctuations. Mismatched thermal expansion rates can lead to cracking or delamination of the epoxy, reducing its protective effectiveness. Selecting the appropriate epoxy formulation that matches the thermal characteristics of the components is essential.

Curing Conditions

The curing conditions, including temperature and time, play a significant role in the final properties of the encapsulated epoxy. Maintaining the correct curing temperature for heat-cured systems is crucial to ensure complete and uniform curing. UV-curable systems require controlled exposure to UV light to achieve proper curing. Deviations from recommended curing conditions can result in under-cured or over-cured epoxy, impacting performance.

Long-Term Stability

While epoxy encapsulation provides excellent initial protection, long-term stability must also be considered. Exposure to UV light, extreme temperatures, and chemicals over extended periods can degrade the epoxy, potentially compromising its protective properties. To ensure continued performance, select epoxies with proven long-term stability and conduct rigorous testing for specific applications.

Future Trends in Electronics Encapsulation Epoxy

Advancements in Epoxy Formulations

The field of encapsulation epoxy is continuously evolving, with ongoing research and development aimed at improving performance and expanding applications. Advancements in epoxy formulations include the development of more thermally conductive epoxies, environmentally friendly formulations, and epoxies with enhanced mechanical properties. These innovations will further enhance the protection and reliability of electronic components.

Integration with Emerging Technologies

As emerging technologies such as flexible electronics, wearable devices, and Internet of Things (IoT) applications gain traction, encapsulating epoxy will be crucial in ensuring their durability and performance. Flexible and stretchable epoxy formulations are being developed to accommodate the unique requirements of these technologies, enabling their widespread adoption.

Sustainable and Eco-Friendly Solutions

With increasing emphasis on sustainability, the development of eco-friendly encapsulation solutions is gaining importance. Researchers are exploring bio-based and recyclable epoxy formulations to reduce the environmental impact of encapsulation processes. These sustainable solutions aim to balance performance with environmental responsibility.

Conclusion

Electronics encapsulation epoxy is a critical component in protecting and enhancing electronic devices. Its ability to shield components from environmental factors, provide mechanical stability, and improve thermal management makes it indispensable across various industries. Manufacturers can make informed decisions to ensure the reliability and longevity of their electronic products by understanding the importance, types, applications, and advantages of encapsulation epoxy. As technology advances, encapsulation epoxy will remain at the forefront, adapting to new challenges and driving innovation in the electronics industry.

For more about choosing the best electronics encapsulation epoxy: protecting and enhancing electronic devices, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.