Flip chip epoxy adhesive glue for strong underfill bonding in surface mount SMT component and electronic PCB circuit board

Flip chip epoxy adhesive glue for strong underfill bonding in surface mount SMT component and electronic PCB circuit board

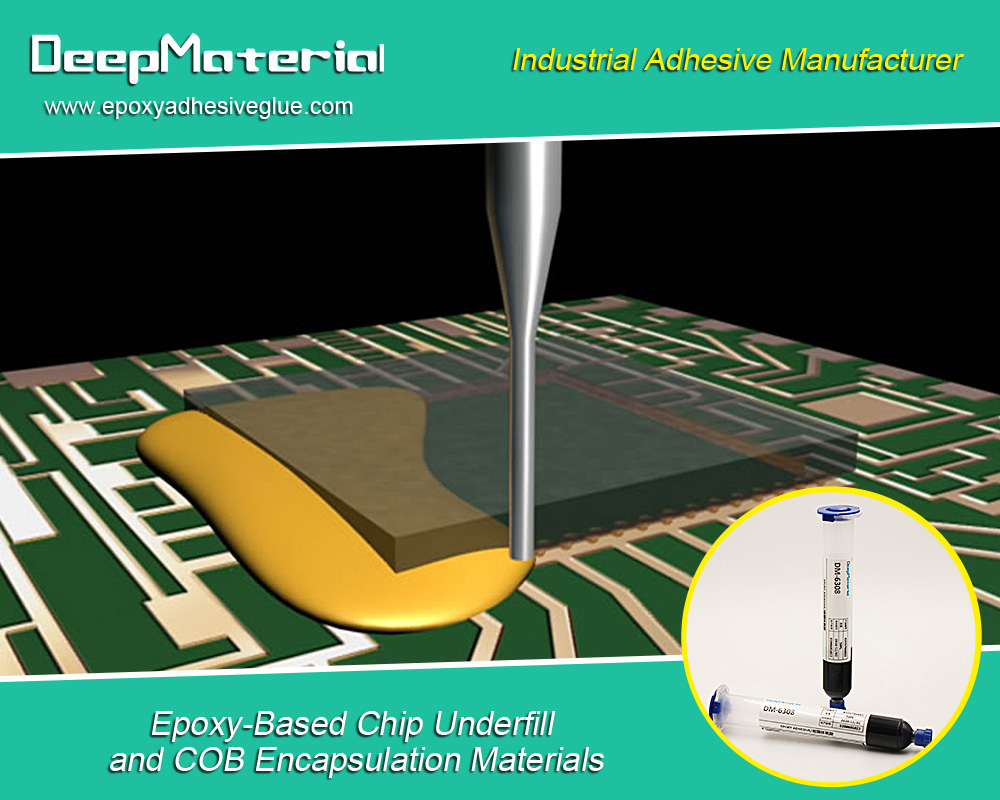

Flip chip bonding involves the flipping of the chip and then attachment. A conductive polymer or solder bump between the substrate and the chip serves as a mechanical and electrical interconnection. Chip adhesives are created to ensure better electrical performance, especially in high-frequency applications.

You can choose between different interconnection options, which depend on the application. Different companies offer these services, which are made of polymer and ceramic substrates. Adhesive or solder interconnection systems can be applied. There are different interconnecting areas involved in chip interconnection.

Adhesive interconnections

In this kind of system, non-oxidizing gold acts as the bump material. It can be combined with titanium-tungsten UBM. The gold bump can be provided by buying a wire binder or electroplated from the stud bump. This is a ball bond bearing a wire tail. The adhesives used here are anisotropically or isotropically conductive.

Epoxy is a good example of an isotropic adhesive. For it to work well, silver flake particles are added. This adhesive is dip transferred or printed to the substrate bond pads or IC bumps. After curing and assembly, a mechanical bond is formed between the IC bump and the substrate. This contrast the solder system where the bond formed is metallurgical.

The anisotropic conducting adhesives include a polymer matrix that has conducting spheres embedded. These are applied to the contacts and chip area in the form of film or paste. The chip is pressed into the substrate, and the conducting sphere is then compressed. This captures them between the substrate pad and the IC bump. This leads to one of the most reliable interconnects after the polymer cures.

The anisotropic conductive adhesive type has an advantage in acting as the underfill. In many other similar applications, a polymer underfill material has to be applied between the substrate and the chip. This reduces thermomechanical stress that acts on the interconnects. The underfill has to be dispensed along the edges of the chip, and after that, it can be drawn into the volume between the substrate and chip through capillary forces.

Advanced Adhesive used in electronics

Different adhesive materials can be used in one package as needed. This depends on the need at hand. Thermally conductive adhesives are considered advanced adhesives. These are the adhesives responsible for bonding the heat sink and the chip.

Thermal expansion can be reduced. This is related to the mismatch between the substrate and the chip. An underfill material can be added where there is space between the solder joints. The underfill process is intricate, and the right filler needs to be used.

RFID bonding

This can refer to bonding RFID tags to different items or chip-to-tag bonding. RFID stands for radio frequency identification. This usually involves an antenna and a microchip. The antenna gives a frequency that is then detected by readers. These tags are widely used in ticketing, transport cards, entry fobs, security tags, library books, ski passes, and bank cards. They can also be used in applications like tool tracking, inventory management, logistics, medical equipment, and vehicle tracking.

These tags don’t need a battery as they derive power from the readers. In such a case, some adhesives can be used in binding RFID. To bond the chop to the tag, epoxy adhesive can be used. Pressure-sensitive adhesives can also be used on the basic tags.

For more about flip chip adhesive glue for strong underfill bonding in surface mount SMT component and electronic PCB circuit board,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/case-in-usa-american-partners-chip-underfill-solution/ for more info.