How to re-imagine your photographic imaging technology for better business success using Camera Module Bonding Adhesives

How to re-imagine your photographic imaging technology for better business success using Camera Module Bonding Adhesives

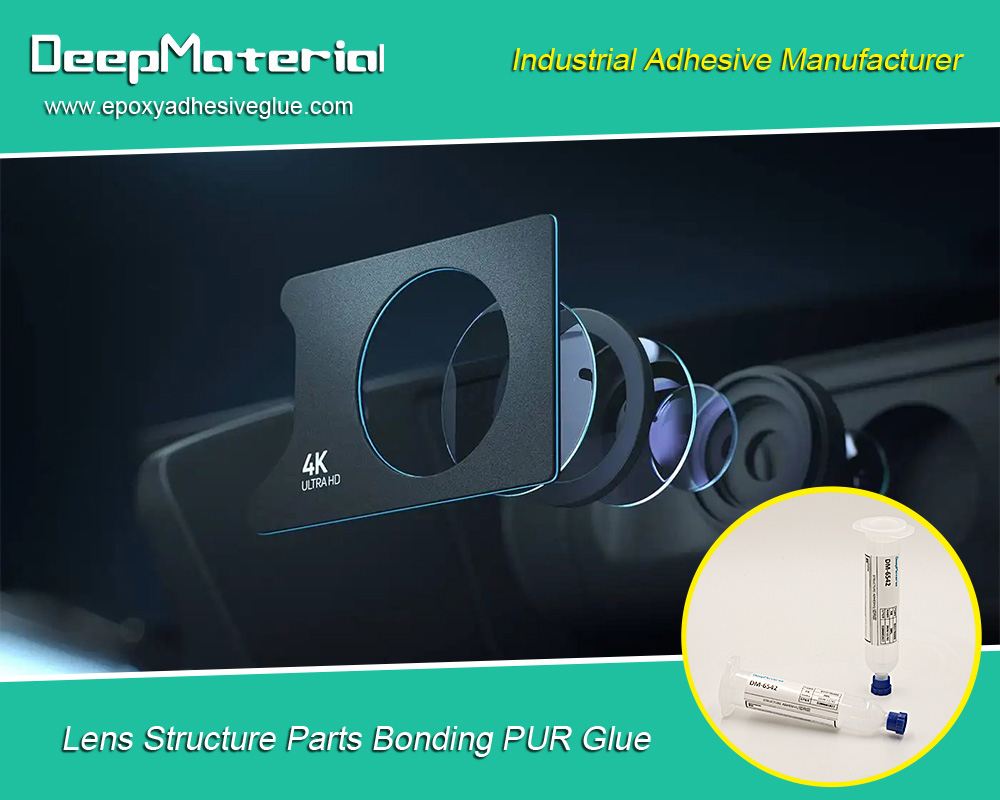

The camera module is an organized component of the camera. It is used to capture images primarily for viewing by humans. The camera module features an aperture, an IR filter, a lens, an image sensor, and various other components. A camera module is widely applied in various camera-based devices. Typically, the camera module is the central photographic imaging technology that makes it possible for the device to take photos and record videos.

Devices with camera modules

Many mobile instruments and devices feature camera modules. Some of the devices with camera modules include smart home equipment, automobile, and smartphones. The camera module should be produced with finesses that it produces quality and high-resolution videos and images. Thanks to the camera module bonding adhesive, this central processing system of the camera can be produced optimally for maximum performance. Camera modules come in various shapes and formats – which usually depend on their application.

Bonding in camera modules

A camera module is a functional part of the camera that consists of several components such as the lens, the image sensor, and the aperture. This is the photographic brain of the camera. Without this essential component, the instrument will not function optimally. The production of the module ensures the optimal operation of the camera. The use of adhesive binders with low viscosity helps to bond various components of the module to form a single unified product.

Re-imagining your photographic imaging technology

When camera module bonding adhesives are applied in assembly lines, this helps to enhance the technology of the production process. With the bonds applied systematically, the viewer experience is maximized. The use of adhesives for this sensitive part of the camera usually helps to provide the following benefits:

- High-end camera modules that come with various fictionalizes and features.

- Enhances the precision of the design technology.

- Supports accelerated product development for an increase in daily throughput.

- Increases the efficiency of the camera

- Allows the camera module to be produced in different shapes and sizes.

- Ensure that all components on the camera modules are tightly attached and locked onto the printed circuit board (PCB).

How to re-imagine your photographic imaging technology using Camera bonding adhesive

Camera bonding adhesive uses a special manufacturing bonding process that involves the joining of multiple substrates. In this case, the components are part of the camera module. The process usually requires exceptional positional precision to complete.m It uses an adhesive such as epoxy or acrylic to complete the process. The adhesive in this case is acting as the binder in the module. In other to bond all the elements of the module efficiently, the following steps should be followed:

1). Degreasing: Degreasing is the first stage of the degreasing process. During this stage, the surfaces or components to be bonded are reared adequately. It helps to remove the grease or contaminants present in the individual components of the module. The presence of grease or contaminants on the module elements can affect the bond quality. One popular degreasing method is to wipe off the surfaces using a cloth soaked in solvent.

2). Application of the adhesive: The materials that are to be glued with the camera module bonding adhesives are usually degreased and glued together. The adhesive is applied carefully onto the surfaces of the components to be glued together. Adhesives are inorganic and organic. When used to glue camera modules their internal strengths help develop the bond to prevent separation of the surfaces.

3). Curing the adhesive: The final stage of bonding the camera module is by curing. While many adhesives may not need curing, a good amount of glues do. For example, heating is a very popular way to cure adhesive bonds. Through heating, the glue gets heated and it triggers a chemical reaction that strengthens the bond. Many manufacturing companies in the optics industry have large commercial layouts in their facilities where products are cured after the application of adhesive bonds. In camera modules, since the components have a low resistance to heat, this method should be executed efficiently.

Camera module bonding adhesives

The camera module bonding adhesive market comes with various products that are used to put this essential component together. There are various available adhesives for camera module bonding. These include:

- Epoxies: Epoxies are very common adhesives that are used in the production of many consumer goods. Due to their efficiencies, they are also applied in the production of camera modules. Epoxies are essential glues that help bind all components of the module together.

- Acrylics:Acrylics are also commonly used as superglues to bind the different models of the camera. They are also very efficient and work as a suitable base for numerous adhesives.

- Silicones: Silicones are also used for binding camera modules and are super effective in helping the component perform optimally.

The commercial market for camera module bonding adhesives

The camera module bonding glue market is worth billions of dollars. It makes up of many manufacturers of advanced camera module bonding adhesives. These glues are used to assemble and produce reliable camera modules. Due to the use of adhesives, the production cycle time is minimized. This leads to an increased daily throughput for the production facility. Since the demand for superior compact and distinct camera modules has increased, production facilities need to re-imagine their respective photographic imaging technologies. The availability of various camera module-binding adhesives has helped many production engineers to design high-resolution camera systems. These end products are widely applied in various industries such as:

- The defence industry

- The consumer electronics industry

- The healthcare industry

- The gaming industry

- The surveillance/security industry

- The automotive industry, and many more.

Manufacturers of advanced and dependable camera modules rely on innovative adhesives to give products and businesses a competitive edge. Many manufacturers offer a line of cutting-edge adhesives that can be deployed for the bonding of the various camera modules. Multiple grades of adhesives are available for bonding different surfaces/components for the production of optical devices.

For more about choosing how to re-imagine your photographic imaging technology for better business success using Camera Module Bonding Adhesives, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/camera-vcm-voice-coil-motor-glue/ for more info.