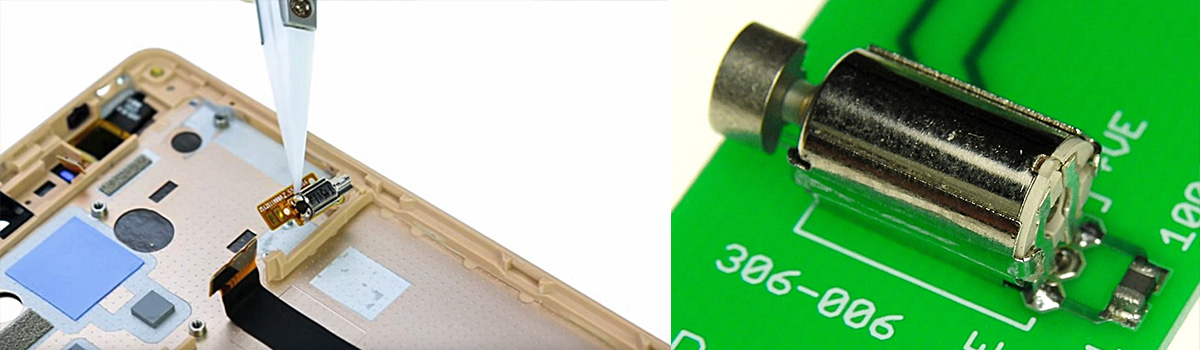

Mini Vibration Motor Bonding

Mechanical Mounting For Vibration Motors To PCBs

Mini Vibration Motor / coin vibration motors, also known as shaftless or pancake vibrator motors. They integrate into many designs because they have no external moving parts, and can be affixed in place with a strong permanent self-adhesive mounting system.

There are many methods for mounting a vibration motor to a Printed Circuit Board (PCB), each with its own advantages and disadvantages. Some techniques are specific to different types of motors, the different mounting techniques are split into four main groups:

· Solder Methods

· Fasteners and Clips

· Injection Moulded Mounts

· Glue and Adhesive Methods

The easy mounting way is the Glue and Adhesive Methods.

Glue and Adhesive Methods

Many of our vibration motors are cylindrical and do not have through-hole pins or are SMT mountable. For these motors, it is possible to use an adhesive such as glue, epoxy resin, or similar product to mount the motor to the PCB or another part of the enclosure.

Due to its simplicity, this is a popular method for prototypes and experimenters. Also, suitable adhesives are widely available and generally inexpensive. This method supports leaded motors and motors with terminals, both allow for flexible mounting options.

Attention must be taken to ensure that the adhesive is strong enough to secure the motor. The strength of the adhesive can be easily improved with the correct application on clean surfaces. Please note a ‘low blooming’ adhesive with high viscosity (i.e. don’t use cyano-acrylate or ‘super glue’ – rather use Epoxy or hot-melt) is strongly recommended to ensure the substance does not enter the motor and glue the internal mechanism.

For extra protection, you may wish to consider our Encapsulated Vibration Motors, which are generally easier to glue.

How to Determine the Right Adhesive for Your DC Mini Vibration Motor

If you’re looking to add some extra vibrancy to your DC mini vibration motor, you’ll want to use the right adhesive. Not all adhesive is created equal, and there are a few key factors to consider when choosing an adhesive. Here are the key points to consider when deciding which adhesive to use: impacts the motor is water resistant and does not damage the motor.

When buying a DC mini vibration motor, it is important to determine the type of adhesive that will work best for the motor. There are different types of adhesive available, and it is important to choose the one that will be the most effective for your motor. If you do not know which adhesive will work best for your motor, you can try using a few different types to see which one is the best for you. Finally, it is important to be sure that the adhesive will not cause any damage to your motor. If it does, you may want to replace the motor.

DeepMaterial Vibration Motoer Adhesive Series

DeepMaterial offers the most stable adhesive for micro electronic moter bonding, it’s easy to operate and automation application.