The Evolution of Industrial Epoxy Adhesive Manufacturers: Innovations, Applications, and Trends

The Evolution of Industrial Epoxy Adhesive Manufacturers: Innovations, Applications, and Trends

In the vast landscape of industrial manufacturing, epoxy adhesives play a crucial role in binding materials with remarkable strength and durability. The growth of industrial epoxy adhesive manufacturers reflects ongoing advancements and increasing demand for these versatile bonding solutions. This article delves into the world of industrial epoxy adhesive manufacturers, exploring their evolution, the innovations driving the industry, and emerging trends that shape their future.

Understanding Industrial Epoxy Adhesives

What Are Epoxy Adhesives?

Epoxy adhesives are thermosetting polymers known for their exceptional bonding properties. Formed by the reaction between epoxy resins and hardeners, these adhesives offer:

- High Strength: Excellent shear and tensile strength.

- Durability: Resistant to impact, chemicals, and environmental factors.

- Versatility: Can bond various materials, including metals, plastics, and composites.

Key Applications

Epoxy adhesives are used in various industries, including:

- Automotive: For assembling and repairing vehicle components.

- Aerospace: In bonding structural elements and composite materials.

- Construction:For floorings, structural repairs, and waterproofing.

- Electronics:In potting and encapsulating electronic components.

The Role of Industrial Epoxy Adhesive Manufacturers

The Market Landscape

Industrial epoxy adhesive manufacturers are pivotal in producing adhesives that meet diverse needs across industries. The market is characterized by:

- Global Reach:Manufacturers serve a wide geographical area, catering to regional and international demands.

- Specialization:Companies often focus on specific applications or industries, offering tailored solutions.

- Competition:With numerous players, innovation, and quality are key differentiators.

Innovations in Epoxy Adhesive Technology

Innovations in epoxy adhesive technology are revolutionizing the capabilities and applications of industrial epoxy adhesive manufacturers, enhancing their product offerings and meeting evolving market demands. Recent advances in formulation are leading the way:

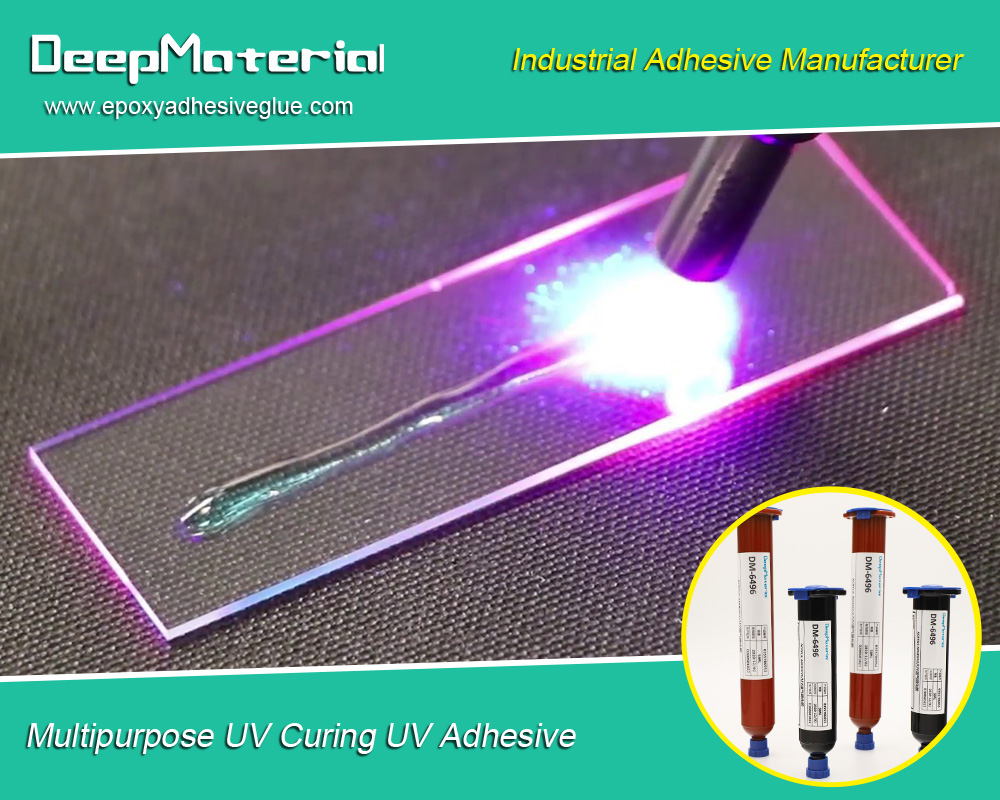

- Improved Curing Processes:Modern epoxy adhesives benefit from faster curing times, increasing efficiency, and improving performance in low-temperature environments. These advancements reduce production times and enhance the adhesive’s overall reliability.

- Enhanced Bonding Strength:New formulations provide superior adhesion to a broader range of challenging surfaces. This improvement addresses the need for more robust and durable bonds in diverse industrial applications, from construction to automotive manufacturing.

- Eco-Friendly Options:There is a growing focus on developing low-VOC (volatile organic compounds) and bio-based adhesives. These eco-friendly options align with global sustainability goals and cater to an increasing demand for greener, less environmentally harmful products.

Customization and specialization are also driving innovation in the industry:

- Custom Formulations:Manufacturers now offer tailored solutions to meet specific industry requirements. Custom formulations improve performance in unique applications, providing more effective and efficient bonding solutions.

- High-Performance Variants:Epoxies engineered for extreme conditions are becoming more common. These high-performance variants are designed to withstand high temperatures, aggressive chemicals, and other challenging environments, expanding the range of applications for epoxy adhesives.

- Modular Systems:There is a rise in modular adhesive systems that include primers, adhesives, and sealants. These comprehensive solutions offer greater convenience and efficiency, designed to work together seamlessly to provide a complete bonding and sealing solution.

Key Trends Shaping the Industry

Sustainability and Environmental Impact

Sustainability is becoming a significant focus for industrial epoxy adhesive manufacturers:

- Green Chemistry: Development of adhesives with reduced environmental impact.

- Recycling Initiatives: Programs to recycle used adhesives and packaging materials.

- Energy Efficiency:Efforts to reduce energy consumption in manufacturing processes.

Digital Transformation

The digital revolution is influencing the adhesive industry:

- Smart Manufacturing:Implementation of Industry 4.0 technologies for better quality control and efficiency.

- Online Platforms:Enhanced access to product information and ordering through digital channels.

- Data Analytics:Data analytics uses data to optimize adhesive formulations and application processes.

Emerging Markets and Applications

New markets and applications are expanding the scope for epoxy adhesives:

- Renewable Energy:Adhesives are used to assemble wind turbines and solar panels.

- Medical Devices:Development of biocompatible adhesives for healthcare applications.

- Advanced Manufacturing:Use in 3D printing and additive manufacturing processes.

Challenges Facing Epoxy Adhesive Manufacturers

Industrial epoxy adhesive manufacturers face various challenges in their operations, significantly impacting their production and market delivery. Navigating complex regulations is a primary concern:

- Chemical Safety:Manufacturers must comply with stringent regulations on hazardous materials and safety standards to ensure the safety of their products and workforce.

- Environmental Regulations:They must adhere to laws concerning emissions and waste management, which can be costly and complex.

Supply chain disruptions further complicate their operations:

- Raw Material Shortages: Variability in the availability of essential components can lead to production delays and increased costs.

- Logistical Challenges:Interruptions in transportation and distribution networks can hinder timely delivery and affect customer satisfaction.

Maintaining quality assurance is also critical:

- Testing and Standards:Manufacturers must conduct rigorous testing to ensure their products meet industry standards and customer expectations.

- Product Reliability:Addressing long-term performance and durability concerns is essential for maintaining product reputation and customer trust.

Future Outlook for Industrial Epoxy Adhesive Manufacturers

The future outlook for industrial epoxy adhesive manufacturers is promising, with several factors contributing to anticipated growth and strategic shifts in the industry.

Anticipated Growth

- Technological Advancements:The industrial epoxy adhesive market is set to expand as continuous innovation introduces new applications and improves existing technologies. Advances in formulation and application methods will likely enhance product performance and open new market opportunities.

- Industrial Expansion: Growing demand from emerging markets and expanding industries such as automotive, aerospace, and construction drives the need for more robust and versatile adhesive solutions. As these sectors grow, so does the demand for high-quality industrial epoxy adhesives.

- Sustainability Trends:There is an increasing emphasis on environmentally friendly solutions. Manufacturers are focusing on developing less harmful adhesives to the environment, using sustainable materials, and aligning with global sustainability goals.

Strategic Directions

- Research and Development:Investment in R&D will be crucial for manufacturers aiming to stay ahead in a competitive market. Developing cutting-edge adhesive technologies that offer superior performance and new functionalities will be essential to meet evolving industry demands and consumer preferences.

- Strategic Partnerships:Collaborating with other industry players, research institutions, and technology providers can foster innovation and facilitate the development of advanced adhesive solutions. These partnerships can also help manufacturers more efficiently access new markets and technologies.

- Customer-Centric Approaches:Enhancing customer service and providing tailored solutions will be vital for maintaining competitive advantage. Manufacturers will likely focus on understanding specific customer needs, offering customized products, and improving overall service to build stronger relationships and drive long-term success.

Conclusion

The industrial epoxy adhesive manufacturing sector is a dynamic and evolving field characterized by significant innovations and growing demands. As manufacturers continue to advance their technologies and adapt to new trends, the future promises a range of exciting possibilities for both the industry and its diverse applications. With a focus on sustainability, technological advancements, and market expansion, industrial epoxy adhesive manufacturers are well-positioned to meet the challenges and opportunities of the modern manufacturing landscape.

For more about choosing the evolution of industrial epoxy adhesive manufacturers: innovations, applications, and trends, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.